Structured Wide Plank Flooring Construction

Constructed Like No Other.

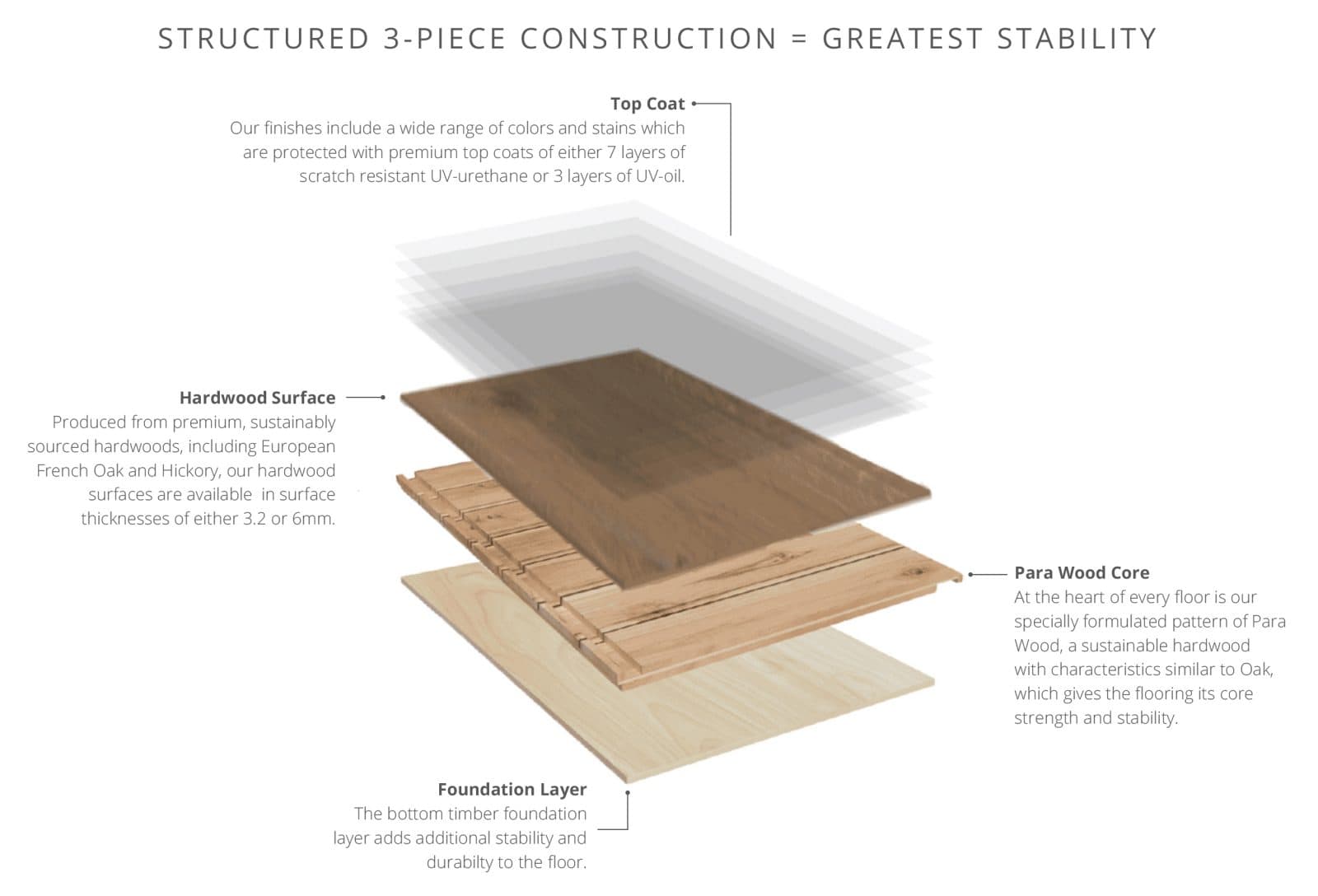

1. The scientifically formulated Para Wood core ensures our floors can withstand external pressure to change.

2. Our floors are less likely than traditional flooring to expand, contract or move when exposed to moisture, humidity or temperature extremes.

3. From foundation to precious hardwood surface each individual layer of our structured flooring is best in-class.

Together the result is unparalleled.

Structured Core

Sawyer Mason Wide Plank Structured Flooring starts with the core. The photo to the left shows Para Wood, a sustainable hard wood with similar characteristics of oak.

The density of Para Wood is the same as French Oak; however, this tree grows year round in ideal climates and quickly enough to offer a sustainable harvest.

Perpendicular Stability

The Para Wood is prepped by being cut into short individual filets.

These filets are placed next to one another and hot pressed together perpendicularly to the length of the board to provide the most strength and stability while still allowing the wood to breathe with changes to the environment.

Angle Sanding

The core pieces are then split and sanded to the proper thickness and width.

Sanding is done at an angle. This is a novel process that allows for a smoother finish and clean lamination to the face of the wood.

Adding the Face

While the core is being prepped, the face wood veneers, made of European French Oak or Hickory, are precisely processed by cutting the boards to the proper lengths and thicknesses.

Subsequently, a process called “blanking” is used to sand and remove imperfections from the boards.

Sustainable Quality

The face veneers are then cut to their final thickness of 3.2mm or 6mm making the thick wear layer of our flooring. Each face veneer is inspected and hand graded for quality control. We use 16 different grades for just our French Oak to ensure we match planks together as close as possible.

The core and the face are then laminated together using a hot press. Our glue produces zero emissions and no off-gassing so our flooring is completely within CARB compliance standards, with less formaldehyde than is released from a typical apple.

Hand Crafting

Before the final coloring can take place, each board of our Sawyer Mason flooring is hand-crafted with a unique style. Yes, each board is cut by hand!

These include planer scraping, true hand scraping, hand brushing and creating natural-looking cracks. The boards are once again inspected for a perfect surface before finishing can take place.

Reactive Color Application

Each board is run through a special spray center that will prepare the face for the reactive stain process and then dried in a special conditioning room.

Conditioning rooms are also used for the fuming process for certain colors that penetrate the face veneer completely. Our conditioning rooms are temperature controlled to strictly manage the effect of the reactive stains, which can vary depending on the slightest change in environment.

Color Calibration by Hand

Reactive stains are then applied and wiped off for special effect which create the truly unique coloring of our Sawyer Mason floors.

The benefit of doing this by hand is certain parts of the wood (ie tighter grain areas) may need more stains where only the eye can see and adjust the amount applied vs a machine.

Top Coat Finishing

Our floors are protected with premium top coats of either seven layers of scratch resistant UV-urethane or three layers of UV-oil before the final quality control tests can take place.

These special finishes, combined with reactive color staining, lend the ability to easily maintain your flooring.

The Final Step

After these many steps, the wide plank boards are then finally bundled together, packaged, and shrink-wrapped.

See our links for all warranty and care instructions for your Sawyer Mason wide plank flooring.